USB Communications Using Microchip PIC

Doug Richards, Dotric Pty Ltd, July 2014.Revised June 2015

Contents

IntroductionHardware Considerations

Program Start Up

Setup Sequence

Application Data

The PC End

Conclusion

Introduction

All Dotric Station Blue model railway controller modules to date have offered Bluetooth or serial port as the means of communication to the controlling computer. In every case the microcontroller at the device end has been the Microchip 18F4520. The popularity of model railway automation has directed development effort towards the desktop computer. Since desktop computers are no longer sold with operating serial ports, it seems logical to offer a USB alternative to Dotric Station Blue customers.Conceptually the idea is to replace the 18F4520 chip with the 18F4550 which additionally has a USB interface. Firmware changes should be restricted to those changes necessary for USB communications. The existing firmware is written in Microchip assembler and runs at 40MHz using a 10MHz crystal. The nearest clock speed available with the 18F4550 is 48MHz using a 20MHz crystal.

The largest single serial port message used by Dotric Station Blue is 15 bytes long. A USB HID (Human Interface Device) interface running at full speed therefore seems possible.

My starting point for this project was this good book:

USB Complete Fourth Edition by Jan Axelson

While this book remains my first reference for everything USB, it is a little short on the bits and bytes level information required for assembler coded firmware. The best single example of Microchip assembler source code for a USB HID I have found is the following:http://www.marcansoft.com/subidos/sdgp.zip

I understand that this source code was based on a similar work produced by Bradley Minch, who is worth a google since he appears in a number of public forums. Also worth a look is the following brief but very informative website:http://www.usbmadesimple.co.uk/

And of course the Microchip data sheet is essential:Microchip PIC18F2455/2550/4455/4550 Data Sheet

Hardware Considerations

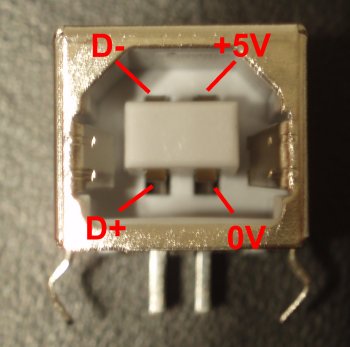

The USB standard B socket proposed to be used with USB equipped Dotric Station Blue modules is shown below:

The capacitor between VDD and circuit zero is routine. I use a 0.22uF tantalum capacitor between VUSB and circuit zero as recommended elsewhere in the datasheet to assist in the regulation of the PIC 3.3V internal power supply.

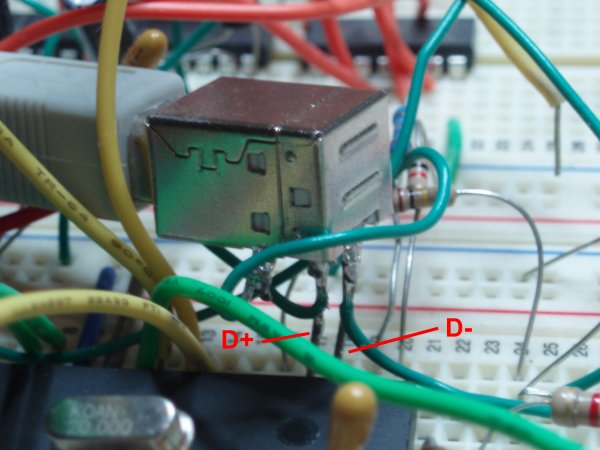

The proposed full speed data lines in fact run at 12 MBits/sec, so consideration must be given to unwanted capacitance effects and matched terminations. However, the PIC does apparently provide the correct termination internally. So provided the leads from the D+ and D- lines are short, from an electrical point of view at least, data transmission should be trouble free. To provide an indication of what a trouble free connection might look like, I have provided a photograph of my breadboard setup below.

Program Start Up

I want full speed USB communications which requires a 48MHz USB clock. I want a 48Mhz CPU clock for my application. Referring to Figure 2.1 in the Microchip PIC18F2455/2550/4455/4550 Data Sheet on Page 24 my 20MHz crystal oscillator needs to be divided down to 4MHz using the PLLDIV MUX and PLL Prescalar. This will achieve the 48MHz USB clock provided USBDIV is one and the FSEN flag is set in the UCFG register. My 48Mhz CPU clock is achieved by using the CPUDIV MUX to select a by 2 division of the 96MHz PLL output. FOSC3:FOSC0 needs to be set to one. All this is implemented with the following config settings:CONFIG PLLDIV=5,CPUDIV=OSC1_PLL2,USBDIV=2,FOSC=HSPLL_HS

Referring to the Microchip PIC18F2455/2550/4455/4550 Data Sheet on Page 174, there are 32 end points ranging from EP0 to EP31. Each end point has two sets of the registers BDnSTART, BDnCNT, BDnADRL and BDnADRH. In each case one set is for IN messages and the other set is for OUT messages. For the sake of confusion USB terminology is PC centric, so IN refers to messages being sent by the device and OUT refers to messages being received by the device.BDnSTAT contains the UOWN flag which determines whether you or the microcontroller core "owns" the BDnSTAT, BDnCNT, BDnADRL and BDnADRH registers. BDnSTAT is also used to read and set DATA0/DATA1. DATA0/DATA1 is used to check for the correct sequencing of USB messages. If you are having trouble getting USB communications to work then there is a good chance that the DATA0/DATA1 sequencing is not correct. BDnCNT contains the message length. BDnADL and BDnADRH contain the starting address for the actual USB message either sent or received.

One important sentence on page 174 that I totally missed the first time I read the text is:

Although they can be thought of at Special Function Registers, the Buffer Descriptor Status and Address registers are not hardware mapped ...

Perhaps more to the point, these registers need to implemented by yours truly! Additionally these registers and associated buffers occupy pages 4 and 5 of data memory. Fortunately 18F4550 has an extra two pages of data memory over the 18F4520 I am replacing. Unfortunately I have to move the data that was on pages 4 and 5 to pages 6 and 7. My buffer descriptor status and address register definitions are as follows:

- #define BD0OSTAT 0x400

- #define BD0OCNT 0x401

- #define BD0OADRL 0x402

- #define BD0OADRH 0x403

- #define BD0ISTAT 0x404

- #define BD0ICNT 0x405

- #define BD0IADRL 0x406

- #define BD0IADRH 0x407

- #define BD1OSTAT 0x408

- #define BD1OCNT 0x409

- #define BD1OADRL 0x40A

- #define BD1OADRH 0x40B

- #define BD1ISTAT 0x40C

- #define BD1ICNT 0x40D

- #define BD1IADRL 0x40E

- #define BD1IADRH 0x40F

- #define BD0OCNT 0x401

- #define BD0OSTAT 0x400

The more relevant USB related parts of my start up sequence are shown below:

- WaitForUSBConnection

- btfss USBVoltage ; Wait until a connected voltage is detected

- bra WaitForUSBConnection

- movlw (1 << UPUEN) + (1 << FSEN)

- movwf UCFG ; Internal pullup & transceiver on

- clrf USTAT

- movlw (1 << USBEN)

- movwf UCON

- movwf UCFG ; Internal pullup & transceiver on

- SingleEndedZero

- btfsc UCON, SE0

- bra SingleEndedZero ; Loop until out of single ended cond

- movlw (1 << TRNIE) | (1<< URSTIE)

- movwf UIE ; Set up USB Interrupt

- movlw (1 << USBIE)

- movwf PIE2

- movlw ((1 << GIE) + (1 << PEIE)) ; Start interrupts

- movwf INTCON

- movlw (1 << USBEN) ; Try again

- movwf UCON

- movwf UIE ; Set up USB Interrupt

The existing Dotric Station Blue code uses interrupts to detect serial port activity and uses circular buffers to pass data to and from the main program. So to retain this structure, I have set up similar interrupts on USB activity. The TRNIE flag is used to detect transmission activity and the URSTIE flag is used to detect a USB reset. Once these interrupts have been connected up the USB enable is attempted again.

My interrupt routine is shown, in part below:

- btfss UIR, URSTIF

- bra NotUSBReset

- call USBReset

- NotUSBReset

- btfss UIR, TRNIF

- bra NotUSBInterrupt

- CheckTransaction

- movlw B'01111000'

- andwf USTAT, w

- btfss STATUS, Z

- andwf USTAT, w

- bra NotEndPointZero

- call EndPointZero

- bra ClearUSBInterrupt

- movlw B'01111000'

- NotEndPointZero

- call EndPointOne

- ClearUSBInterrupt

- bcf UIR, TRNIF

- btfsc UIR, TRNIF ; check FIFO

- bra CheckTransaction

- bcf UIR, TRNIF

Of note is the behaviour of the FIFO described in the Microchip PIC18F2455/2550/4455/4550 Data Sheet on Page 170. Once the TRNIF flag is cleared it is important to check it in case it has been immediately reset indicating that there is more transmission activity in the queue.

Two fundamental differences between USB and serial port communication are: firstly unlike serial port communications USB is not full duplex, and secondly unlike serial port commmunications, preemptive messages cannot be sent from a device with USB. Even HID devices like keyboards rely on being polled by the PC. So in terms of this interrupt routine, there use to be a specific serial port send interrupt to indicate when the serial port send buffer was empty and more data could be sent. There is no equivalent with USB.

Setup Sequence

Referring to figure 4.1 on page 91 of USB Complete Fourth Edition by Jan Axelson, this complete scenario must occur if the coveted "The device is working properly" message is to appear in Windows Device Manager for your device.If you don't have the book on hand the sequence is:

- Reset

- GetDescriptor (Device)

- Reset

- SetAddress

- GetDescriptor (Device)

- GetDescriptor (Configuration - short)

- GetDescriptor (Configuration - long)

- GetDescriptor (String - language id)

- GetDescriptor (String - Product)

- GetDescriptor (String - language id)

- GetDescriptor (String - Product)

- GetDescriptor (Device)

- GetDescriptor (Configuration - short)

- GetDescriptor (Configuration - long)

- GetStatus (Device)

- SetConfiguration

Reset

Reset detection is in my interrupt routine described above. Basically the URSTIF flag in the UIR register is used to detect a reset. Once detected, your reset routine is an ideal place to intialize all your USB related variables.In my reset routine I start off by flushing out the FIFO described in the Microchip PIC18F2455/2550/4455/4550 Data Sheet on Page 170:

- bcf UIR, TRNIF

- bcf UIR, TRNIF

- bcf UIR, TRNIF

- bcf UIR, TRNIF

- bcf UIR, TRNIF

- bcf UIR, TRNIF

- movlw 16

- lfsr FSR1, UEP0

- movlw 16

- ClearEP

- clrf POSTINC1

- decfsz WREG, f

- bra ClearEP

- decfsz WREG, f

- clrf POSTINC1

- movlb 4

- movlw EP0MAXPS

- movwf BD0OCNT, 1

- movwf BD0ICNT, 1

- movwf BD1OCNT, 1

- movwf BD1ICNT, 1

- movlw EP0MAXPS

- movlb 4

- clrf BD0OADRL, 1

- movlw 0x3F

- movwf BD0IADRL, 1

- movlw 0x7F

- movwf BD1OADRL, 1

- movlw 0xBF

- movwf BD1IADRL, 1

- movlw 0x05

- movwf BD0OADRH, 1

- movwf BD0IADRH, 1

- movwf BD1OADRH, 1

- movwf BD1IADRH, 1

- movlw 0x3F

- clrf BD0OADRL, 1

- movlw (1<<UOWN)|(1<<DTSEN)

- movwf BD0OSTAT, 1

- movwf BD1OSTAT, 1

- movlw (1<<DTSEN)

- movwf BD0ISTAT, 1

- movwf BD1ISTAT, 1

- clrf BSR

- movwf BD0OSTAT, 1

- movlw (1<<UOWN)|(1<<DTSEN)

- clrf UADDR

- clrf UIR

- movlw (1 << EPHSHK) | (1 << EPOUTEN)| (1 << EPINEN)

- movwf UEP0

- movlw (1 << EPHSHK) | (1 << EPCONDIS) | (1 << EPOUTEN)| (1 << EPINEN)

- movwf UEP1

- movwf UEP0

- movlw (1 << EPHSHK) | (1 << EPOUTEN)| (1 << EPINEN)

EndPoint Zero

Once the reset routine is organised, the rest of the 16 step setup sequence is a case of processing incoming messages and responding as necessary. All setup messages occur on endpoint zero (EP0). While I find the processing of incoming (OUT) messages a little bit idiosyncratic, I find the processing of outgoing (IN) messages to be completely weird. This weirdness I believe, is due to the inability to send preemptive messages. Basically the procedure is to arm the appropriate message buffer and then wait for an IN interrupt from the PC before actually sending the message. A DATA0/DATA1 toggle actually needs to occur between the arming and the sending.Another unusual feature of this process is the dual functionality of the not so special USB status registers as described in Microchip PIC18F2455/2550/4455/4550 Data Sheet on Page 177. In particular:

When the BD and its buffer are owned by the SIE, most of the bits in BDnSTAT take on a different meaning.

Before we start processing messages there is a handy piece of special register structure that may not be immediately apparent. Referring to the Microchip PIC18F2455/2550/4455/4550 Data Sheet on Page 171, if you apply a mask for bits 2 to 6 of USTAT you instantly have the address of the correct BDnSTAT register on page 4 of data memory.

So my interrupt routine described earlier has detected a transaction using the TRNIF flag in UIR and has used USTAT to determine which endpoint the message is on. I then use USTAT again to get the contents of the appropriate BDnSTAT register while it is still owned by the SIE as follows:

- movlw 0x04

- movwf FSR1H

- movf USTAT, w

- andlw B'01111100'

- movwf FSR1L

- movf POSTINC1, w

- andlw B'00111100'

- movwf Token , 1

- movwf FSR1H

- movlw 0x04

- #define TOKEN_OUT (0x01<<2)

- #define TOKEN_ACK (0x02<<2)

- #define TOKEN_IN (0x09<<2)

- #define TOKEN_SETUP (0x0D<<2)

- #define TOKEN_ACK (0x02<<2)

- #define TOKEN_OUT (0x01<<2)

Finally there is TOKEN_SETUP which indicates that a setup message has been received from the PC. At this point we know that the received message is in the message buffer referred to by the not so special registers BD0OADRL and BD0OADRH. I have found that I actually only need five variables out of received setup messages and I obtain them as follows:

- movff BD0OADRL, FSR1L

- movff BD0OADRH, FSR1H

- movff POSTINC1, bmRequestType

- movff POSTINC1, bRequest

- movff POSTINC1, bDscIndexADRL

- movff POSTINC1, bDscTypeADRH

- movff POSTINC1, UsbLength

- movff POSTINC1, UsbLength

- movff POSTINC1, UsbLength ;Length of the required response

- movff BD0OADRH, FSR1H

- movff BD0OADRL, FSR1L

- movlb 4

- movlw EP0MAXPS

- movwf BD0OCNT, 1

- movlw (1 << DTSEN)

- movwf BD0ISTAT

- clrf BSR

- movlw EP0MAXPS

- movlb 4

So to the first byte in the received message - bmRequestType. It contains the following information:

- bits 0 to 5: 00000 = device, 00001 = interface, 00010 = endpoint, 00011 = other

- bits 6 to 7: 00 = standard, 01 = class, 10 = vendor

- bits 0 to 5: 00000 = device, 00001 = interface, 00010 = endpoint, 00011 = other

- movlw 0x21

- cpfseq bmRequestType, 1

- bra SetUp21

- movlw (1<<UOWN)|(1<<DTS)|(1<<DTSEN)

- bra SetUpReady

- movlw 0x21

- SetUp21

- movlw (1<<UOWN)|(1<<DTSEN)

- SetUpReady

- movlb 4

- movwf BD0OSTAT, 1

- clrf BSR

- movwf BD0OSTAT, 1

- movlb 4

Moving on to the second byte in the received message - bRequest. It may have one of the following values:

- #define NO_REQUEST 0xFF

- #define USB_REQUEST_GET_STATUS 0

- #define USB_REQUEST_CLEAR_FEATURE 1

- #define USB_REQUEST_SET_FEATURE 3

- #define USB_REQUEST_SET_ADDRESS 5

- #define USB_REQUEST_GET_DESCRIPTOR 6

- #define USB_REQUEST_SET_DESCRIPTOR 7

- #define USB_REQUEST_GET_CONFIGURATION 8

- #define USB_REQUEST_SET_CONFIGURATION 9

- #define USB_REQUEST_GET_INTERFACE 10

- #define USB_REQUEST_SET_INTERFACE 11

- #define USB_REQUEST_GET_STATUS 0

- #define NO_REQUEST 0xFF

- #define USB_DESCRIPTOR_DEVICE 0x01

- #define USB_DESCRIPTOR_CONFIGURATION 0x02

- #define USB_DESCRIPTOR_STRING 0x03

- #define USB_DESCRIPTOR_INTERFACE 0x04

- #define USB_DESCRIPTOR_ENDPOINT 0x05

- #define USB_DESCRIPTOR_DEVICE_QUALIFIER 0x06

- #define USB_DESCRIPTOR_OTHER_SPEED 0x07

- #define USB_DESCRIPTOR_INTERFACE_POWER 0x08

- #define USB_DESCRIPTOR_OTG 0x09

- #define USB_DESCRIPTOR_CONFIGURATION 0x02

- #define USB_DESCRIPTOR_DEVICE 0x01

- #define DSC_HID 0x21

- #define DSC_RPT 0x22

- #define DSC_PHY 0x23

- #define DSC_RPT 0x22

- #define DSC_HID 0x21

| Value | Variable | Description |

|---|---|---|

| 0x12 | bLength | Size of this message in bytes |

| 0x01 | USB_DESCRIPTOR_DEVICE | Descriptor Type - Device |

| 0x0111 | bcdUSB | USB Specification release number 1.11 |

| 00 | bDeviceClass | Class is specified in interface descriptor |

| 00 | bDeviceSubClass | |

| 00 | bDeviceProtocol | |

| 0x40 | bMaxPacketSize | EP0 maximum packet size |

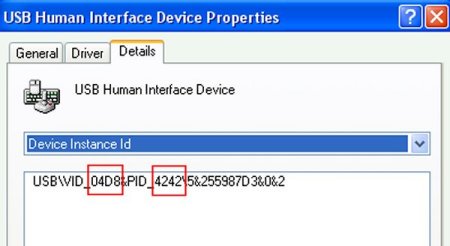

| 0x04D8 | idVendor | Microchip vendor id |

| 0x4242 | idProduct | any number really - refer to text below |

| 0x0100 | bcdDevice | device release number |

| 0x01 | iManufacturer | used to reference string in string descriptors |

| 0x02 | iProduct | used to reference string in string descriptors |

| 00 | iSerialNumber | A zero indicates that there is no serial number |

| 0x01 | bNumVConfigurations | Number of configurations |

Firstly it should be noted that when sending 16 bits variables, the low bytes are sent first. The idVendor and idProduct values provided here actually appear in the Device Instance Id property string displayed by Device Manager on the connected PC. As shown these values appear directly after the strings "VID_" and "PID_" and importantly provide the means of identifying your device and obtaining a handle for it on the PC.

The process of sending this response is a case of loading up the message buffer referred to by the not so special BD0IADRL and BD0IADRH registers and setting BD0ICNT to the message length - 0x12 in this case. I use the following routine to set BD0ISTAT and keep the DATA0/DATA sequence on track:

- movlb 4

- movf BD0ISTAT, w, 1

- xorlw 1 << DTS

- andlw 1 << DTS

- iorlw (1 << UOWN) | (1 << DTSEN)

- movwf BD0ISTAT, 1

- clrf BSR

- bcf UCON, PKTDIS

- movf BD0ISTAT, w, 1

- movlb 4

Moving on with the 16 step setup sequence, we get to SetAddress. Now the USB address for my device is saved to special register UADDR. During the reset routine UADDR was set to zero. So up to this point all the setup requests have been sent to USB address zero. Not surprisingly, once the SetAddress request has been successful, all subsequent setup requests will be to the USB address supplied in the SetAddress request.

The third byte in the received message - bDscIndexADRL is in fact the USB address that the PC has allocated to my device. However, the process is not quite a simple matter of saving this value to UADDR because of that following TOKEN_IN request that will also be using USB address zero. So when I receive the SetAddress request I save the provided USB address as a temporary variable:

- movff bDscIndexADRL, UsbAddrPend

- movlb 4

- clrf BD0ICNT, 1

- movlw (1<<UOWN)|(1<<DTS)|(1<<DTSEN)

- movwf BD0ISTAT, 1

- clrf BSR

- bcf UCON, PKTDIS

- movlb 4

- movff bDscIndexADRL, UsbAddrPend

- ProcessTokenIn

- movlw USB_REQUEST_SET_ADDRESS

- cpfseq bRequest, 1

- bra NotSetAddress

- movff UsbAddrPend, UADDR

- return

- movlw USB_REQUEST_SET_ADDRESS

- NotSetAddress

- movlw USB_REQUEST_GET_DESCRIPTOR

- cpfseq bRequest, 1

- return

- goto UsbRequestGetDescriptor

- movlw USB_REQUEST_GET_DESCRIPTOR

| Value | Variable | Description |

|---|---|---|

| 0x09 | bLength | Size of this message component in bytes |

| 0x02 | USB_DESCRIPTOR_CONFIGURATION | Descriptor Type - Configuration |

| 0x0029 | wTotalLength | Total length of the long response |

| 0x01 | bNumInterfaces | Number of interface in this configuration |

| 0x01 | bConfigurationValue | Index of this configuration |

| 0 | iConfiguration | Configuration string index |

| 0xC0 | bmAttributes | Attributes - in this case self powered only |

| 0x32 | bMaxPower | Maximum power consumption (100mA) |

| 0x09 | bLength | Size of this message component in bytes |

| 0x04 | USB_DESCRIPTOR_INTERFACE | Descriptor Type - Interface |

| 0 | bInterfaceNumber | Interface number |

| 0 | bAlternateSetting | Alternate setting number |

| 0x02 | bNumEndpoints | Number of endpoints in this interface |

| 0x03 | bInterfaceClass | Interface class (HID) |

| 0 | bInterfaceSubclass | Interface subclass |

| 0 | bInterfaceProtocol | Interface protocol |

| 0 | iInterface | Interface string index |

| 0x09 | bLength | Size of this message component in bytes |

| 0x21 | DSC_HID | Descriptor Type - HID |

| 0x0111 | bcdHID | HID specification release number |

| 0 | bCountryCode | Country code |

| 0x01 | bNumDescriptors | Number of subordinate class descriptors |

| 0x22 | bDescriptorType (DSC_RPT) | Descriptor type (report) |

| 0x0022 | wDescriptorLength | Report descriptor size in bytes |

| 0x07 | bLength | Size of this message component in bytes |

| 0x05 | USB_DESCRIPTOR_ENDPOINT | Descriptor Type - endpoint |

| 0x01 | bEndpointAddress | Endpoint number and direction (1 OUT) |

| 0x03 | bmAttributes | Transfer type - interrupt |

| 0x000F | wMaxPacketSize | Maximum packet size |

| 0x0A | bInterval | Polling interval (milliseconds) |

| 0x07 | bLength | Size of this message component in bytes |

| 0x05 | USB_DESCRIPTOR_ENDPOINT | Descriptor Type - endpoint |

| 0x81 | bEndpointAddress | Endpoint number and direction (1 IN) |

| 0x03 | bmAttributes | Transfer type - interrupt |

| 0x000F | wMaxPacketSize | Maximum packet size |

| 0x0A | bInterval | Polling interval (milliseconds) |

One may observe that this message is structured like 5 descriptor response messages combined into one. In fact, I have structured my code to be able to respond to Get Descriptor types USB_DESCRIPTOR_CONFIGURATION, USB_DESCRIPTOR_INTERFACE, DSC_HID and USB_DESCRIPTOR_ENDPOINT when each is requested separately. However in reality I believe that if wTotalLength is set to the total length of all of these responses in that first short GetDescriptor - Configuration response, then the PC will "swallow the whole lot in one shot" when it requests the long response.

While many of the variables here are merely transcriptions from other code samples, a few variables are noteworthy. The bmAttributes value of 0xC0 indicates a self powered device without remote wakeup. The bNumEndpoints value of 0x02 indicates that this configuration has 2 endpoint descriptors. The bInterfaceClass value of 0x03 indicates that this device is a HID. The wDescriptorLength value of 0x0022 indicates that our response to the GetDescriptor - Report (DSC_RPT) request will be 34 bytes long. The two bEndpointAddress values of 0x01 and 0x81 indicate that both incoming and outgoing application data streams occur on endpoint EP1. The two bInterval values of 0x0A indicate a polling interval of 10ms. Given a proposed message length of 15 bytes, this will give me an effective data rate of 15 bytes per 10ms or 12,000 baud.

A wMaxPacketSize value of 0x000F is used for both the incoming and outgoing application data streams. This seems like a repeat of the information supplied in the Report Descriptor described next, but maybe the information here has more to do with the operation of the interrupts than the report content. I understand that the maximum possible packet size here is 64 bytes. Now if your report size is bigger than this I believe that muliple interrupts will be triggered to fill your report with multiple 64 byte chunks. If this sounds like you it might pay to revisit my earlier comments about the FIFO.

The 34 byte response to the GetDescriptor - Report (DSC_RPT) request just mentioned is as shown:

| Code | Value | Description |

|---|---|---|

| 0x06 | 0xFFA0 | Usage page |

| 0x09 | 0x01 | Usage |

| 0xA1 | 0x01 | Collection |

| 0x09 | 0x03 | Usage |

| 0x15 | 0 | Logical minimum |

| 0x26 | 0x00FF | Logical maximum |

| 0x75 | 0x08 | Report size |

| 0x95 | 0x0F | Report count |

| 0x81 | 0x02 | Input |

| 0x09 | 0x04 | Usage |

| 0x15 | 0 | Logical minimum |

| 0x26 | 0x00FF | Logical maximum |

| 0x75 | 0x08 | Report size |

| 0x95 | 0x0F | Report count |

| 0x91 | 0x02 | Output |

| 0x0C | End collection |

First point to be noted is that the format of this response is quite different to the others. Instead of following a preset format, it has codes immediately followed by values. Once again many of my values simply follow other code samples. However, it should be noted that my response describes one input and one output. Both have a report size of 8 and a report count of 15 indicating that both my incoming and outgoing messages consist of fifteen eight bit bytes.

Noteable for its absence is code 0x85 - Report Id. The Report Id of each endpoint is added to the front of every message sent and received by the connected PC. The Report Id is thus used to associate specific messages with specfic endpoints at the PC end. I have not included Report Id values in my GetDescriptor - Report (DSC_RPT) response because of course, I am using only one endpoint for all my application data. In the absence of a specified Report Id value, the default Report Id value is zero.

Referring back to the 16 step setup sequence, there is the GetDescriptor - String request . Now in my response to the GetDescriptor - Device request I provided the string indices for iManufacturer and iProduct. These indices will appear in turn in the GetDescriptor - String requests in the third byte - bDscIndexADRL. Also appearing in turn will be an index value of zero which is a request for language id. The only language I am supporting at this stage is English which has a language id of 0x0409. My response is therefore:

| Value | Variable | Description |

|---|---|---|

| 0x04 | bLength | Size of this message in bytes |

| 0x03 | USB_DESCRIPTOR_STRING | Descriptor Type - String |

| 0x0409 | wLangId | Language Id |

The responses to the iManufacturer and iProduct indices simply consist of the message size, descriptor type (USB_DESCRIPTOR_STRING) and any desired string. These strings must be in 16 bit unicode format, which for English letters consist of ASCII characters in the low bytes and zeroes in the high bytes. Keep in mind that low bytes are sent first. Now I wouldn't spent too much time on this exercise. I have been unable to find my manufacturer string anywhere on my PC. My product string appears in a balloon in the bottom right hand corner of the monitor when my device is first installed, but is thereafter gone forever unless my device fails, in which case the product string seems to become prevalent again.

Last but certainly not least is the SetConfiguration request. Basically this is the "Thunderbirds are go" message. I respond to this one with a zero length message.

Application Data

My basic stategy is have all of my Dotric Station Blue application messages occurring through endpoint EP1. The procedure for processing messages on endpoint EP1 is similar to the one used for endpoint EP0. Namely, my interrupt routine described earlier detects a transaction using the TRNIF flag in UIR and uses USTAT to determine which endpoint the message is on. I then use USTAT again to get the contents of the appropriate BDnSTAT register while it is still owned by the SIE as follows:- EndPointOne

- movlw 0x04

- movwf FSR1H

- movf USTAT, w

- andlw B'01111100'

- movwf FSR1L

- movf POSTINC1, w

- andlw B'00111100'

- movwf Token , 1

- movlw TOKEN_OUT

- cpfseq Token

- movwf FSR1H

- bra NotTokenOut1

- call ReceivedInterrupt

- return

- movlw 0x04

- NotTokenOut1

- movlw TOKEN_IN

- cpfseq Token

- bra NotTokenIn1

- call SendInterrupt

- return

- movlw TOKEN_IN

- NotTokenIn1

- return

My USB converted incoming message routine - ReceivedInterrupt is therefore fairly straight forward. I simply load up my circular buffer from the appropriate USB message buffer as shown:

- ReceivedInterrupt

- movff BD1OADRL, FSR2L

- movff BD1OADRH, FSR2H

- movff BD1OCNT, RecvCount

- movff BD1OADRH, FSR2H

- movff BD1OADRL, FSR2L

- ReadNextByte

- movff POSTINC2, Byte

- .....

- .....

- .....

- Existing application code

- .....

- .....

- decfsz RecvCount

- .....

- bra ReadNextByte

- movff POSTINC2, Byte

- movlw EP0MAXPS

- movlb 4

- movwf BD1OCNT, 1

- movf BD1OSTAT, w, 1

- xorlw(1<<DTS)

- andlw(1<<DTS)

- iorlw (1<<UOWN)|(1<<DTSEN)

- movwf BD1OSTAT, 1

- clrf BSR

- bcf UCON, PKTDIS

- movlb 4

- movlw EP0MAXPS

- movlb 4

- btfss BD1ISTART, UOWN, 1

- bra UownGood

- clrf BSR

- return

- .....

- .....

- Existing application code

- .....

- .....

- movlb 4

- movlw 0x0F

- movwf BD1ICNT, 1

- movf BD1ISTAT, w, 1

- xorlw(1<<DTS)

- andlw(1<<DTS)

- iorlw (1<<UOWN)|(1<<DTSEN)

- movwf BD1ISTAT, 1

- clrf BSR

- return

- .....

- movlb 4

- SendInterrupt

- return

The PC End

I have seen a number of examples of C# code for PCs interfacing with USB devices and find them rather convoluted. I prefer to use CLR C++ to write a dll that interfaces with my C# code. The FastSerialPort dll described in the article Improving the Performance of Serial Ports Using C#: Part 2 may be suitably modified for the purpose.So starting with the ReceiveMessage routine, reading one byte at a time does not work with USB, instead a whole USB message buffer must be read with one ReadFile command. Recall that I specified a 15 byte message in my GetDescriptor - Report (DSC_RPT) response on the PIC. Recall also that a Report Id is always added to the front of every message. Applying these modifications the ReceiveMessage routine is now in part as shown:

- BYTE buffer[16];

- if (ReadFile(m_hUSBPort, buffer, 16, &readSize, &osRead) == 0)

- {

- DWORD error = GetLastError();

- if (GetLastError()== ERROR_IO_PENDING)

- GetOverlappedResult(m_hUSBPort, &osRead, &readSize, TRUE);

- else

- break;

- DWORD error = GetLastError();

- }

- for(int iii = 0; iii < (int)readSize; iii++)

- BYTE buffer[16];

The OpenPort routine is much simpler with USB. All that is really required is the CreateFile command:

- m_hUSBPort = CreateFile(

- portName,

- GENERIC_READ | GENERIC_WRITE,

- FILE_SHARE_WRITE | FILE_SHARE_READ,

- NULL,

- OPEN_EXISTING,

- FILE_FLAG_OVERLAPPED,

- NULL);

- GENERIC_READ | GENERIC_WRITE,

- portName,

First you need to populate an instance of HDEVINFO:

HDEVINFO DeviceInfoSet = SetupDiGetClassDevs(&classGuid, NULL, NULL, DIGCF_DEVICEINTERFACE | DIGCF_PRESENT);

The class GUID required here is for the HID class - {4D1E55B2-F16F-11CF-88CB-001111000030}. I actually obtain the required value for classGuid from a C# string as follows:

- array

^ guidData = guid.ToByteArray(); - pin_ptr

data = &(guidData[0]); - _GUID classGuid = *(_GUID*)data;

- pin_ptr

- int memberIndex = 0;

- SP_DEVICE_INTERFACE_DATA DeviceInterfaceData;

- ZeroMemory(&DeviceInterfaceData, sizeof(SP_DEVICE_INTERFACE_DATA));

- DeviceInterfaceData.cbSize = sizeof(SP_DEVICE_INTERFACE_DATA);

- while( SetupDiEnumDeviceInterfaces(DeviceInfoSet, NULL, &classGuid, memberIndex, &DeviceInterfaceData))

- {

- SP_DEVICE_INTERFACE_DATA DeviceInterfaceData;

- DWORD bufferSize = 0;

- memberIndex++;

- DWORD bufferSize = 0;

- int memberIndex = 0;

- if (!SetupDiGetDeviceInterfaceDetail( DeviceInfoSet, &DeviceInterfaceData, NULL, 0, &bufferSize, NULL))

- {

- DWORD Error = GetLastError();

- if (Error != ERROR_INSUFFICIENT_BUFFER)

- return false;

- DWORD Error = GetLastError();

- }

- PSP_DEVICE_INTERFACE_DETAIL_DATA detailBuffer = (PSP_DEVICE_INTERFACE_DETAIL_DATA)(new BYTE[bufferSize]);

- detailBuffer->cbSize = sizeof(SP_DEVICE_INTERFACE_DETAIL_DATA);

- if (!SetupDiGetDeviceInterfaceDetail(DeviceInfoSet, &DeviceInterfaceData, detailBuffer, bufferSize, NULL, NULL))

- {

- DWORD Error = GetLastError();

- return false;

- DWORD Error = GetLastError();

- }

- if (!SetupDiGetDeviceInterfaceDetail( DeviceInfoSet, &DeviceInterfaceData, NULL, 0, &bufferSize, NULL))

- SP_DEVINFO_DATA deviceInfoData;

- deviceInfoData.cbSize = sizeof(deviceInfoData);

- if (!SetupDiEnumDeviceInfo(DeviceInfoSet, memberIndex, &deviceInfoData))

- {

- deviceInfoData.cbSize = sizeof(deviceInfoData);

- DWORD Error = GetLastError();

- return false;

- DWORD Error = GetLastError();

- }

- WCHAR deviceInstanceId[1024];

- if (!SetupDiGetDeviceInstanceId(DeviceInfoSet, &deviceInfoData, deviceInstanceId, sizeof(deviceInstanceId), NULL))

- {

- DWORD Error = GetLastError();

- return false;

- DWORD Error = GetLastError();

- }

- SP_DEVINFO_DATA deviceInfoData;